Reduce defects - Clean before solder paste print

Contamination control is a critical part of achieving zero defects in high-end manufacturing processes.

Leading producers use advanced analytics to drive process improvements and data from major Tier 1 manufacturers identifies particulate contamination as the main cause of defects in PCBA.

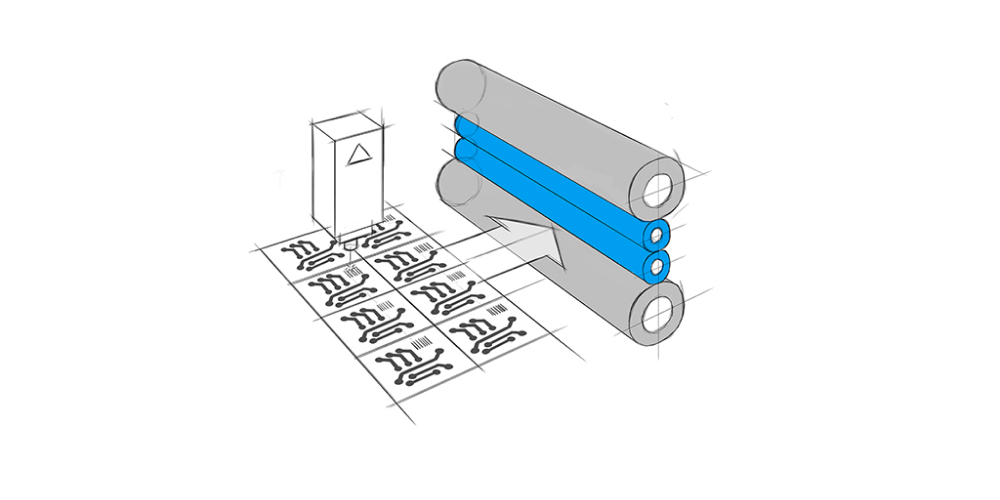

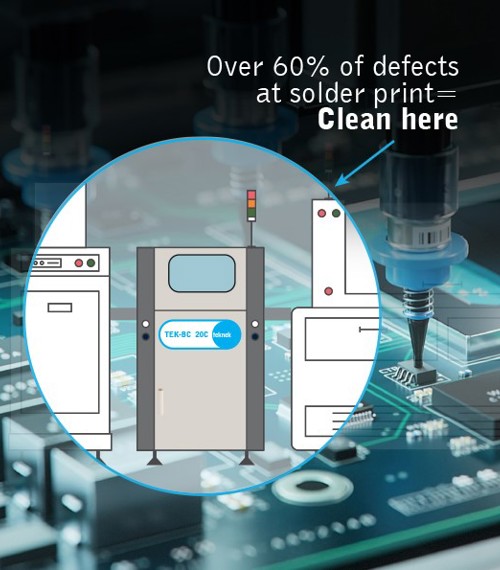

Drilling and routing are major sources of contaminating particles but other processes such as laser marking generate substantial amounts of particles too. Every stage of the production process is individually analysed and results show that one process step, Solder Paste Print, is responsible for 60% of all defects.

As a result, leading producers deploy Teknek contact cleaning solutions as standard to remove contamination at this critical process step.

Eliminate FOD, Elevate Performance

The prevalence of Foreign Object Debris (FOD) has become a significant concern in the Surface Mount Technology (SMT) and Printed Circuit Board Assembly (PCBA) sector.

It can disrupt component placement accuracy, leading to soldering defects, electrical shorts, and compromised device functionality. Moreover, FOD-induced failures may surface post-production or during product operation, incurring substantial costs related to rework, repair, and potential recalls.

By proactively integrating Teknek board cleaners into production lines, manufacturers can mitigate FOD risks and enhance the quality and performance of electronic devices.

SMT Assembly & PCBA

Surface Mount Technology (SMT) has revolutionized electronic assembly processes, enabling faster production cycles and higher component densities.

However, as electronic devices become increasingly complex, competing needs for performance and ever smaller footprints means that ensuring the reliability and functionality of SMT assemblies becomes paramount.

By incorporating Teknek cleaners into assembly processes, leading producers enhance component placement accuracy, minimize soldering defects, and improve overall product reliability.

Typical Applications for Teknek machines:

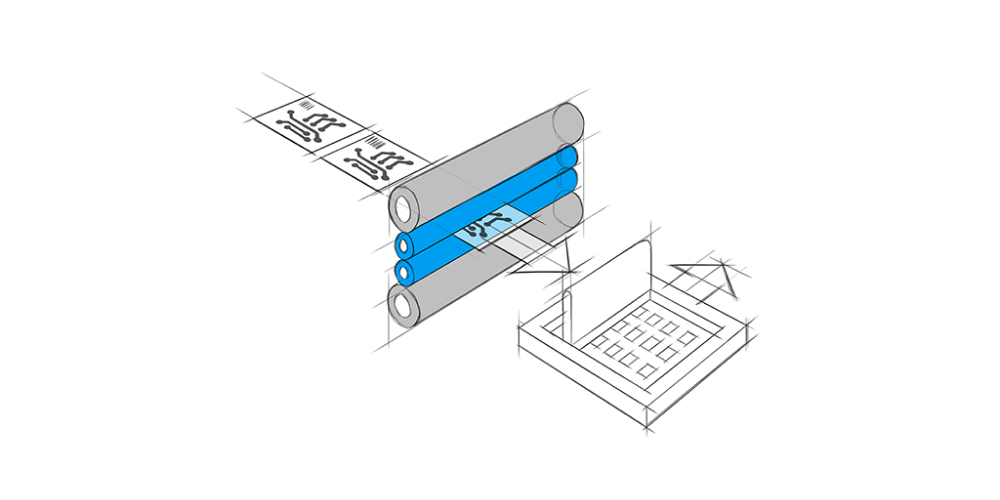

- After Laser Marking (eliminates contamination created by laser marking)

- Before Solder Paste Print (removes particles and prevents blockage of stencil ensuring quality of solder paste print)